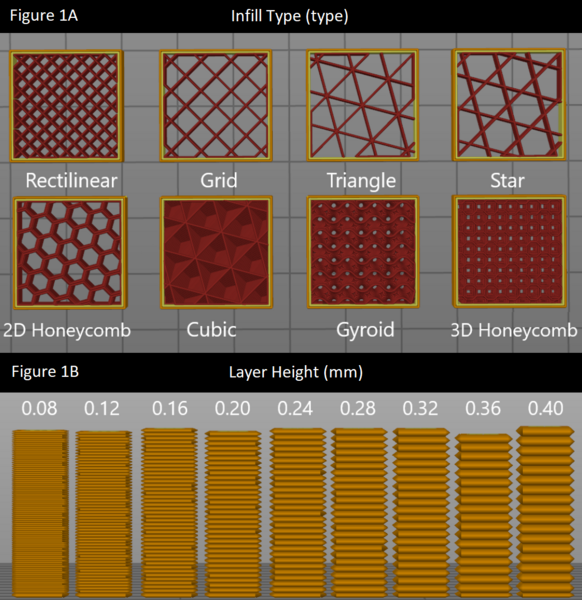

In this study, the authors test different infill patterns to determine which would be the strongest and most durable for 3D printing applications, which have become an integral part of many facets of life.

Read More...Optimizing 3D printing parameters: Evaluating infill type and layer height effects on tensile fracture force

In this study, the authors test different infill patterns to determine which would be the strongest and most durable for 3D printing applications, which have become an integral part of many facets of life.

Read More...Testing Epoxy Strength: The High Strength Claims of Selleys’s Araldite Epoxy Glues

Understanding the techniques used to improve the adhesion strength of the epoxy resin is important especially for consumer applications such as repairing car parts, bonding aluminum sheeting, and repairing furniture or applications within the aviation or civil industry. Selleys Araldite epoxy makes specific strength claims emphasizing that the load or weight that can be supported by the adhesive is 72 kg/cm2. Nguyen and Clarke aimed to test the strength claims of Selley’s Araldite Epoxy by gluing two steel adhesion surfaces: a steel tube and bracket. Results showed that there is a lack of consideration by Selleys for adhesion loss mechanisms and environmental factors when accounting for consumer use of the product leading to disputable claims.

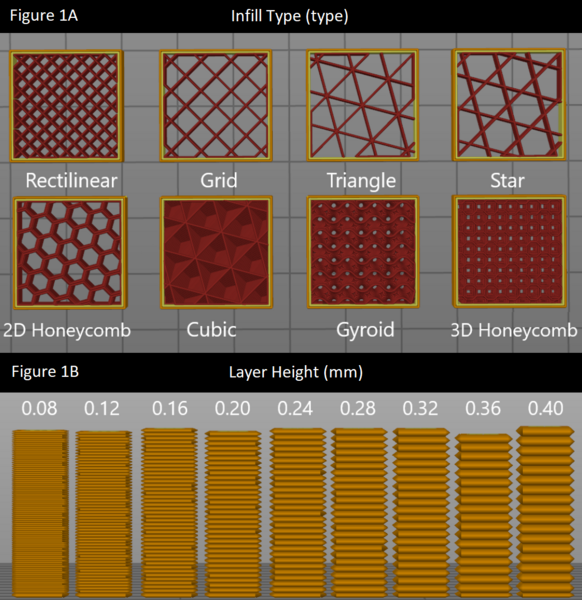

Read More...The effects of plasticizers on the mechanical properties and chemical composition of a gelatin biopolymer

Here, in an effort to identify alternatives to oil-based plastic, the authors sought to investigate the effects of plasticizers on the mechanical properties and chemical composition of gelatin bioplastic matrices. Through measurements of their tensile strength and elongation at break, along with FTIR spectroscopy, they identified 3% w/v polyethylene glycol film as having the best performance in their study..

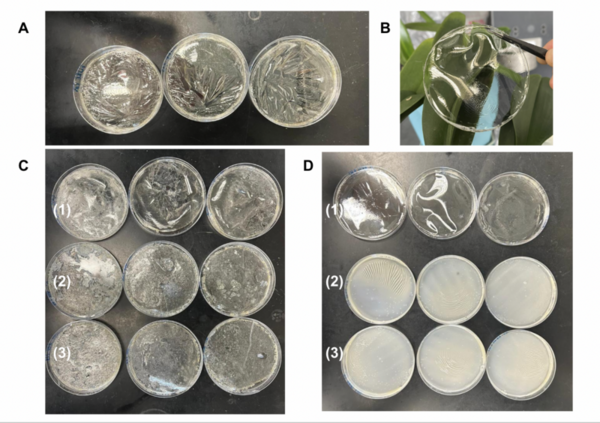

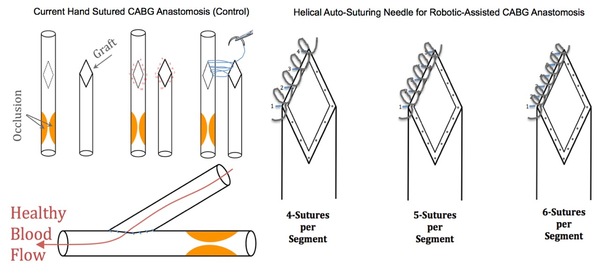

Read More...A Novel Method for Auto-Suturing in Laparoscopic Robotic-Assisted Coronary Artery Bypass Graft (CABG) Anastomosis

Levy & Levy tackle the optimization of the coronary artery bypass graft, a life-saving surgical technique that treats artery blockage due to coronary heart disease. The authors develop a novel auto-suturing method that saves time, allows for an increased number of sutures, and improves graft quality over hand suturing. The authors also show that increasing the number of sutures from four to five with their new method significantly improves graft quality. These promising findings may help improve outcomes for patients undergoing surgery to treat coronary heart disease.

Read More...Statistical evaluation of the effects of surface processing on aerospace fastener tested strength

In the aerospace industry, various surface processing or coatings are widely used. However, no detailed research on the aerospace fastener tensile and double shear strength variation due to surface processing has been conducted. Thus, the purpose of this study was to systematically evaluate the effect of surface processing on the standard aerospace fastener's tensile and shear properties.

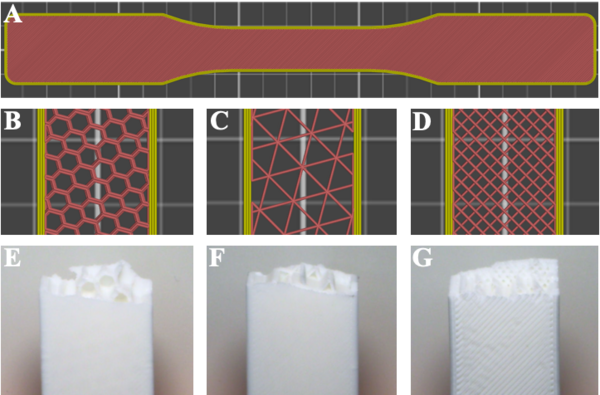

Read More...Influence of Infill Parameters on the Tensile Mechanical Properties of 3D Printed Parts

Manufacturers that produce products using fused filament fabrication (FFF) 3D printing technologies have control of numerous build parameters. This includes the number of solid layers on the exterior of the product, the percentage of material filling the interior volume, and the many different types of infill patterns used to fill their interior.This study investigates the hypothesis that as the density of the part increases, the mechanical properties will improve at the expense of build time and the amount of material required.

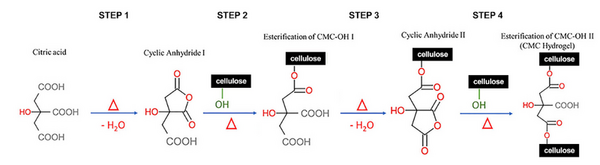

Read More...Utilizing sorbitol to improve properties of cellulose-based biodegradable hydrogels

Hydrogels are commonly used in medicine, pharmaceuticals, and agriculture. Hydrogels absorb water by swelling and re-release this water by diffusion. This study sought to synthesize a biodegradable, cellulose-based hydrogel that is more effective at absorbing and re-releasing water than those produced by current methods. We tested the compressive strength of both the dry and swollen gels and the tensile strength of the swollen gels to elucidate the gel structure.

Read More...A systematic study of cut-resistant socks for hockey players

Estimating the Young’s Modulus of spaghetti with a buckling experiment

The Young's Modulus of a structural material is a measure of its elasticity and is defined as the ratio of the tensile stress to tensile strain. This study aims to investigate the Young's Modulus of pasta with different diameters.

Read More...Development of novel biodegradable bioplastics for packaging film using mango peels

Here the authors explored the development of biodegradable bioplastic films derived from mango peels as a sustainable solution to plastic pollution and greenhouse gas emissions from fruit waste. They optimized the film's mechanical properties and water resistance through adjusting processing conditions and incorporating plasticizers and a hydrophobic coating, ultimately demonstrating its potential as a bacteriostatic and biodegradable alternative to conventional plastic food wrap.

Read More...