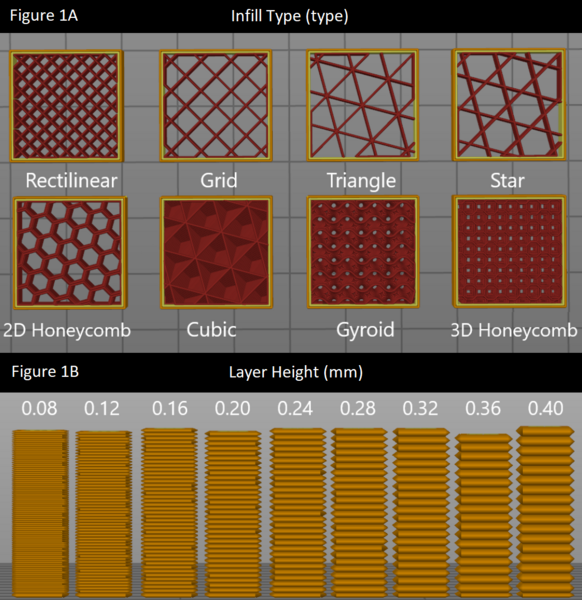

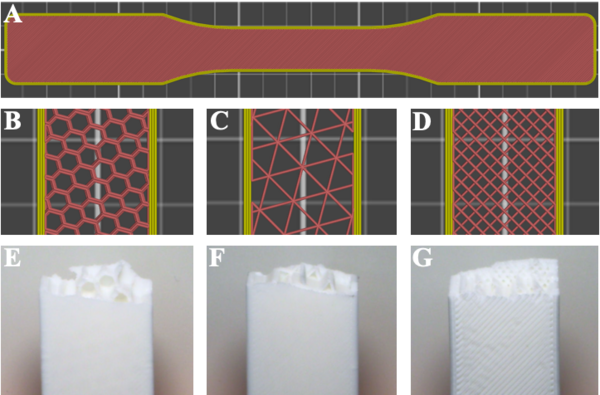

Manufacturers that produce products using fused filament fabrication (FFF) 3D printing technologies have control of numerous build parameters. This includes the number of solid layers on the exterior of the product, the percentage of material filling the interior volume, and the many different types of infill patterns used to fill their interior.This study investigates the hypothesis that as the density of the part increases, the mechanical properties will improve at the expense of build time and the amount of material required.

Read More...