Fabrication of CuSbS2 Solar Cells by Sulfurization of Thermally Evaporated Metal Stacks

(1) Toledo Early College High School, Toledo, Ohio, (2) University of Toledo, Toledo, Ohio

https://doi.org/10.59720/16-018

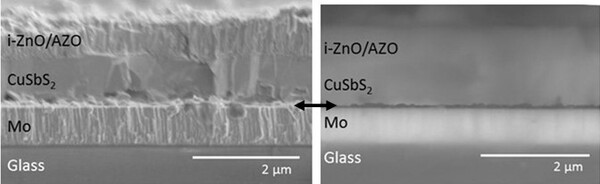

We report on the deposition of thin films of chalcostibite (CuSbS2) created by sulfurization of thermally evaporated metal stacks. We found by X-ray diffraction that thermally evaporated copper and antimony metal films, which were annealed for 1.5 hours at 400°C followed by rapid sulfurization at 400°C for 15 minutes, exhibit the CuSbS2 crystalline phase. The films have high optical absorption with a band gap of ~1.6 eV. Our CuSbS2- based thin film solar cells had low conversion efficiency, due to the formation of a layer of molybdenum disulfide (MoS2) and/or secondary phases at the molybdenum back contact layer–CuSbS2 interface. To negate this problem, we applied a layer of single-walled carbon nanotubes (SWCNT) on the molybdenum back contact. This arrangement allowed for a better junction between the molybdenum and CuSbS2 layers. With the addition of SWCNT, our best cell under AM 1.5 illumination exhibited an open circuit voltage (Voc) of 321 mV, a short circuit current density (Jsc) of 3.76 mA/cm2, and a fill factor of 27%, resulting in a conversion efficiency of 0.33%. This work shows that for effective solar devices, it is critical that device layers are electrically aligned to allow for better electron passage. In the case presented here, we increased the efficiency by creating a passageway for electrons through the device by eliminating the formation of MoS2. This can be achieved by inserting single-walled carbon nanotubes (SWCNTs) that allow a better junction between the molybdenum and CuSbS2 layers. An alternative may include changing sulfur quantity, sulfurization time, or temperature.

This article has been tagged with: