Environmentally-friendly graphene conductive ink using graphene powder, polystyrene, and waste oil

(1) Kang Chiao International School - Taipei Campus, New Taipei City, Taiwan , (2) New Taipei City Yuteh Private Bilingual School, New Taipei City, Taiwan, (3) National Taiwan University, Department of Chemical Engineering, Taipei, Taiwan, (4) Kang Chiao International School - Taipei Campus, New Taipei City, Taiwan

https://doi.org/10.59720/21-144

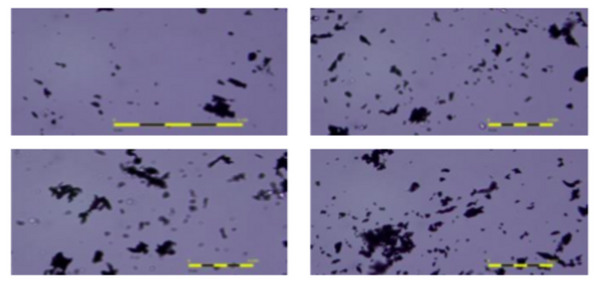

Waste oil and polystyrene are main sources of pollution that endanger our health. This project proposes an effective, environmentally-friendly method of producing conductive ink using expired waste oil, polystyrene, and graphene. We compared three types of differently-sized graphene powder, two of which are ball-milled. We hypothesized that the ink made with the graphene with the longest milling time will have the best conductivity and the lowest viscosity, thus the easiest to spread. Furthermore, we hypothesized that the film-forming properties would increase with the addition of more polystyrene, regardless of the type of powder. We also determined the microscopic lamellar pattern of the graphene powder. Increased ball-milling time resulted in more polarized powder distribution; smaller pieces of graphene were stacked together as well as larger flakes. We assessed the correlation between the conductivity of graphene powder and its free volume, highlighting how the graphene and waste oil bounded together. We later explored a combination of waste oil with graphene and evaluated the oil absorption of graphene. An ink with a conductive coating film resistance below 100 Ohm was made by altering the proportions of the composition of graphene, polystyrene, and oil. We determined that the best ink recipe consists of mineral oil (baby oil), graphene milled for 2.5 hours, and a polystyrene-to-graphene ratio of 0.5 to 1 because it compromises between low resistance, moderate viscosity, good spreadability, and good film-forming properties. This work has important implications on developing a novel way to recycle waste into applicable conductive ink.

This article has been tagged with: