Here the authors explored the development of biodegradable bioplastic films derived from mango peels as a sustainable solution to plastic pollution and greenhouse gas emissions from fruit waste. They optimized the film's mechanical properties and water resistance through adjusting processing conditions and incorporating plasticizers and a hydrophobic coating, ultimately demonstrating its potential as a bacteriostatic and biodegradable alternative to conventional plastic food wrap.

Read More...

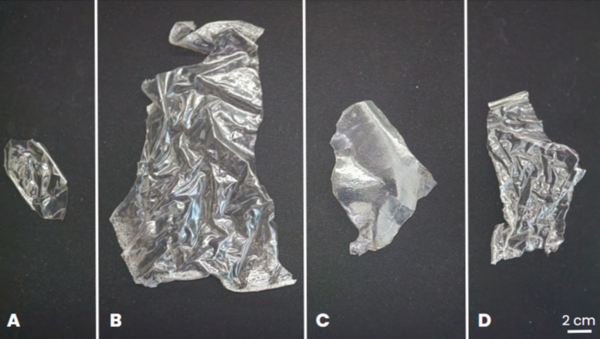

.jpg)