A Taste of Sweetness in Bioplastics

(1) Kang Chiao International School, New Taipei City, Taiwan

https://doi.org/10.59720/18-079

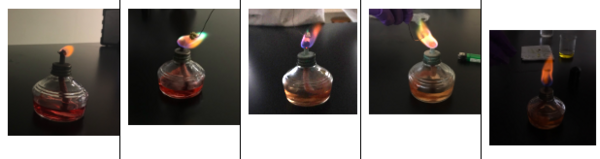

In this study, we used an agricultural waste commonly found in Taiwan, sweet potato peels, to make bioplastic. We manipulated the amount of glycerol added when making the plastic and measured the resulting plastic’s properties. We predicted that reducing the amount of glycerol would result in a firmer and less malleable plastic because glycerol acts as a plasticizer, preventing the polymers from forming brittle, inflexible structures. The process began with extracting starch from sweet potato peels. We also ran the peels and their starch under a flame test to investigate the type of metal ions they contained, which we determined to be Cu2+ and Cu+, respectively. Then, we made bioplastic by heating up the starch mixture with acetic acid, different amounts of glycerol, and water. Allowing the mixture to set, we were left with a thin piece of plastic film. In the final stage of the experiment, we conducted a stress test to evaluate the malleability of plastic mixtures. Our results supported our initial prediction as the plastic containing the greatest amount of glycerol expanded the most, indicating that it had the greatest malleability. We concluded that the ratio of 1:2.4 starch to glycerol would yield the ideal plastic film with a flexible yet firm texture, properties which allow for the plastics to be molded into different structures yet still retain their shapes. Even though we didn’t manage to make a substantial amount of plastic, we have determined a recipe for making bioplastics from agricultural waste such as sweet potato peels. This opens a door for possibilities in slowing down the rate of pollution caused by widespread use of conventional plastics.

This article has been tagged with: