Impact of NaCl concentration in crystalline nanocellulose for printed ionic dielectrics

(1) Panther Creek High School, Cary, North Carolina, (2) Department of Electrical and Computer Engineering, Duke University, Durham, North Carolina, (3) Department of Electrical and Computer Engineering, Duke University, Durham, North Carolina; Department of Chemistry, Duke University, Durham, North Carolina

https://doi.org/10.59720/22-240

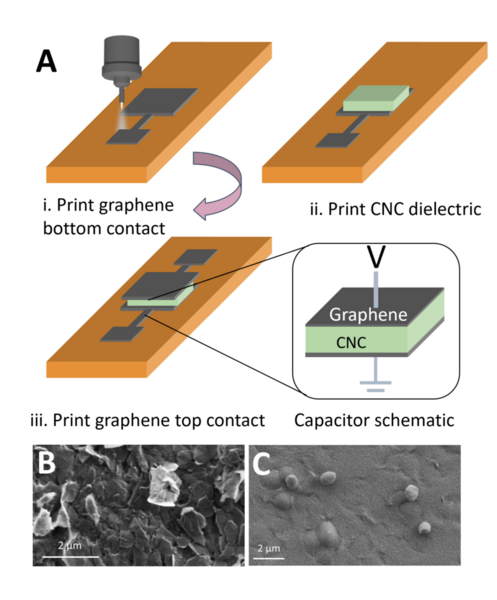

While electronics continue to be an integral part of nearly every aspect of our lives, there is a growing need for more environmentally friendly electronic materials and manufacturing processes. The use of crystalline nanocellulose (CNC) as a biodegradable dielectric material has recently gained interest due to its high capacitance at low voltages and compatibility with additive manufacturing techniques, such as printing. The addition of salt to the CNC has shown improved performance in transistor applications, but a thorough study optimizing the addition of NaCl in CNC capacitors has not been completed. We hypothesized that increasing the NaCl concentration altered the charging characteristics of the CNC. In this work, we verified this hypothesis by measuring the charging and discharging characteristics for CNC capacitors with varying NaCl concentrations and extracting the resistance-capacitance (RC) delay and charging current. These aerosol jet printed capacitors consisted of graphene top and bottom electrodes and a CNC dielectric sandwiched between the electrodes. The results reveal a minimum charging current at a NaCl concentration of 0.05%, independent of the applied voltage, and a minimized RC delay at NaCl concentrations above 0.1% with applied voltages below 2 V. These findings show that there are trade-offs that must be managed between RC delay and charging current, thus the NaCl concentration must be optimized for each application. This work is another significant step in understanding the electrical properties of CNC so that this environmentally friendly material may one day be utilized in commercially available electronics.

This article has been tagged with: