Testing Different Polymers and Boron Nitride Nanotube Properties in Fabrication of Ion-selective Membranes

(1) East Brunswick High School, East Brunswick, New Jersey, (2) Fluid Hydrodynamics Laboratory, Rutgers University, New Brunswick, New Jersey

https://doi.org/10.59720/20-104

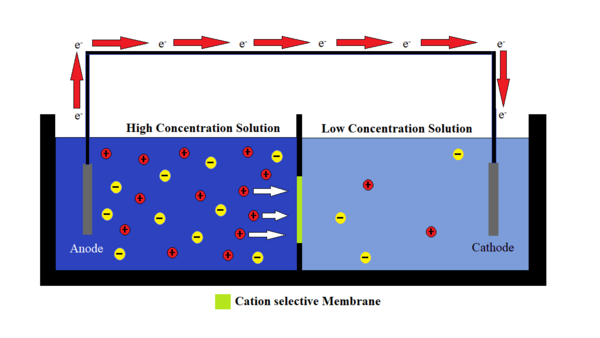

One largely untapped source of clean energy is the use of osmotic gradients where freshwater and saltwater are mixed, for example at estuaries. To harness such energy, charge-selective membranes are needed to separate the anions and cations in saltwater, establishing an electric potential like a battery. The objective of this study was twofold: to investigate the creation of the polymer matrix and test the properties of boron nitride nanotubes, as both are essential in the creation of an ion-selective membrane. The proposed polymer layer has many attractive properties: controllable thickness allowing nanotubes (typically 5-10 microns long) to pass through, being rapidly curable with a UV lamp, easy mounting on other substrates, resistance to O2 and SF6 plasma gas etching, and structural strength to prevent tears. The hypotheses for this study are that the Soltech 704 (SU704) will prove to be the best polymer in terms of both etching and curing results, in addition, the relationship between the magnetic dipole moment and the length of the nanotubes is predicted to be linear. The Soltech 704 is trifunctional, compared to the other difunctional polymers tested, which is why it is predicted to have the highest strength. The dipole moment was hypothesized to be linear with nanotube length, since a longer nanotube allows for more iron oxide particles to attach to it. Out of three polymer samples tested in this study, the mixture known as Soltech 704 showed the best resistance to etching, as well as the highest UV cure rate. These two traits are desirable since they lead to a sturdier membrane and one that is created more quickly. To allow such nanotubes to be aligned, we attached magnetic iron oxide particles and then applied a magnetic field. We then recorded the magnetic dipole moments of nanotubes and compared it to the length of the nanotube. The relationship between dipole moment and length can thus be discovered. Such results can be used to optimize the alignment procedure for the nanotubes, as well as the procedure for curing the polymer.